Sometimes this problem may arise. However, this is a problem that can be common to most of the welders. To some, you may find out that Lincoln Weld Pak 100 wire may start to misbehave.

Sometimes when this happens, you find that the wire feed would cut in and out such that it pops strangely. You may think that the wire is getting stuck, and when stuck, the drive wheels do slip in the welding unit.

At long last, when you decide to do an investigation, you will discover the major issue is exactly on the trigger assembly of the handle. Removing this and putting it in is quite an easy task. Therefore, when you get such a problem, it’s good to carry out an investigation to know where the problem is because you may end up spending a lot of money buying a new welder, yet the problem could be the Lincoln weld 100 wire feed which is having a problem which can be fixed.

This article will take you through what brings about the Lincoln weld pak wire feed problem. I will also go through the steps that we should take when this problem arises.

It is my hope that this article will be of great help to you. When you realize that the Lincoln weld 100 wire feed is the one having a problem, then you can follow the procedure that I am going to give step by step to solve the problem.

Contents

Step by step guide on how to solve Lincoln pak 100 wire feed problem

1. Safety

For safety purposes, it is quiet in order to plug out your welder. It is not advisable to carry out anything on your welder while it’s still connected to electricity. These welding machines should always be treated with caution since they can be dangerous to our lives at some point.

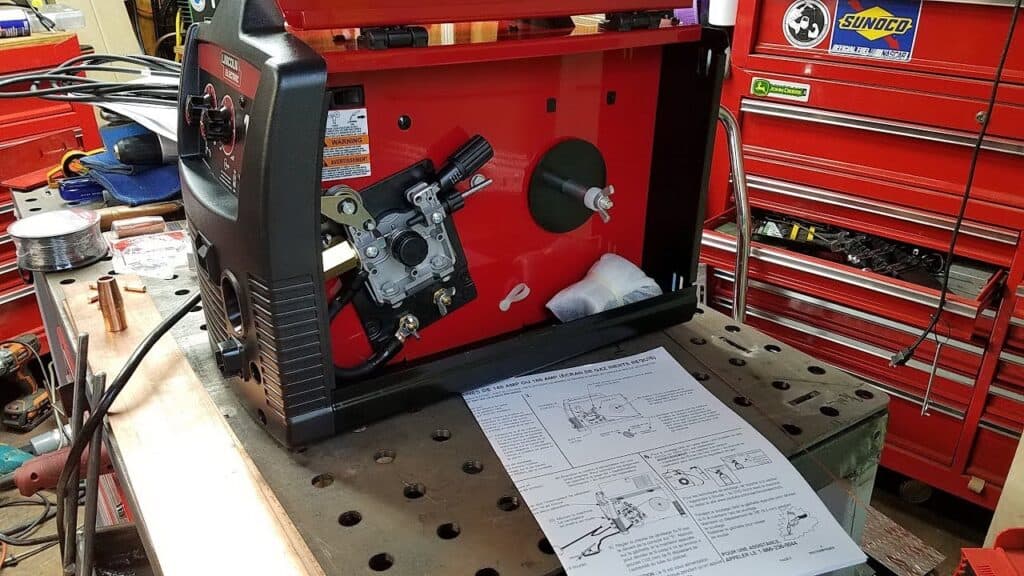

2. Open up the handle

Upon opening the handle, get out the collars below and above the handle by removing the screws. These collars only need a quarter turn to unlock.

After unlocking, pull straight a variety, instead of a standard nut. Do this slowly; you shouldn’t force anything, and you should be able to feel how the nut will just come out with a lot of ease.

I wouldn’t recommend one to use pliers because its parts are made of plastic and easily. If you feel something extra is needed to remove the nuts, then the best option is to get the rough part of a paper towel then wrap it around the nut before making use of the pliers to remove the nuts.

Make sure you don’t think of using oil to make the parts lose. Its switch mechanism normally relies on metal contact and clean metal, and most of the lubricants will not make this happen.

When you manage to get off the handle, you should then separate them with ease into two halves. After pulling the halves away from the beach, the trigger will fall out. It is loaded with a spring, so it can also pop away from its handle a little bit, so you should be ready for that.

3. Inspect inside

On your gun, the trigger operates by pushing forward a small ring of copper against two leads that are bare, making the circuit complete across all. When you have the top half of the shell gun flipped in upside down, the contacts should be apart by 5mm.

These contacts that are bare are usually pressed together and put into small slots of plastics to maintain them in line with the ring of copper. When you observe keenly at the contact’s picture, you will find out that the contact at the top does not sit properly, and in addition to that, the tip that is in contact is pushed down into the gun’s body.

This was done to keep that contact just at that edge of the ring with the copper trigger. This showed that it depends on how the gun was held, the contact could be made, or it could stutter on or even stutter off.

This small misalignment was the reason for the issues. I tend to think the problem could be contact since when it becomes loose, accidentally, it can make the gun bang accidentally, and by doing so, it becomes loose.

This problem can be corrected in a very simple way pushing the contact to where it sits. Glue can be added if one wants. This fix is very easy, and it should not bother anyone to think of going back to buy a new welder.

4. Reseat the trigger

Take the trigger and take it back to where it’s supposed to be housed. Ensure that the small tabs that stick at the back and front are fitting easily into the depressions of the body of the gun. The spring will have some compressions, which will require a finger to put on the trigger so that it can stay in its place.

When certain that everything is okay and the alignments are properly done, you can now close the body of the gun.

Everything that was disconnected should be put back together in an easy way. If things don’t go back to the norm easily, then it means that there is something that has not been corrected. This means that you will be required to go back and confirm if everything is aligned well.

It can be quite tricky to keep hold of the trigger for some time while you place the half on the top of the gun though it can still take a little time to align well. Having done that, the two halves can be held tightly together using one hand and the other hand to screw both the lower and upper collars.

Having done that, the Lincoln weld pak 100 wire feed should be in a position to be used; you can do a test by grabbing some scrap metals and seeing if it works well. If you still experience a problem, it means the source of the problem for your welder is different.

You might be interested to read also our another articles of: Lincoln 210 MP Vs Miller 215 and Hobart 190 Vs. Lincoln 180

Conclusion

Since this is a common problem, I would like to advise welders that if they have issues with the welding machines, it is then advisable to first look at the instructional manual for the welder and see if the problem can be identified. If the problem is with the Lincoln weld 100 wire feed, then the above procedure can help.

If you’re a starter and have difficulties following, you can also seek assistance in the welding industry for quite a while. If all this doesn’t work, you take the machines to experts and the last choice could be buying a new one if all don’t work.