It is entirely normal for a car’s various components to deteriorate over time. The radiator, like other components of the vehicle, deteriorates over time. If it is not maintained routinely, its core, tubes, and housing may break or develop holes.

Car radiators leak and the most obvious sign of a leak is a continuously low coolant level or a green radioactive-looking puddle beneath your vehicle.

Though it may appear challenging, resolving this issue is relatively simple. Epoxy glues in general, and J-B Weld in particular, are capable of withstanding high temperatures.

One may use J-B Weld on a variety of surfaces. Examples of such materials are steel, porcelain, marble, glass, fiberglass, paper, and ceramics. It thus can be used to fix a radiator leak, as we will see in this article.

This post will outline the best steps to take if your radiator is leaky, and you will need to fix it with a J-B weld. Additionally, this article addresses several frequently asked questions. Carefully consider the guidelines in the article and practice them to the latter to ensure that your radiator is repaired correctly.

Contents

Repairing a radiator leak using a J-B weld

The steps are as follows;

Step 1: Remove the radiator cap and remove the water from the system

First, make sure that the radiator has been wholly drained before proceeding with the repair. There are a few requirements that must be completed before the radiator is drained.

The first thing you should do is make sure you haven’t gotten into your car within the last few hours. This requires the use of an incredibly cool engine, so be sure to have one.

Be sure that the cell is not attached to the vehicle’s engine system. This procedure may harm your batteries. Consequently, you will be billed for services that you did not receive.

Next, cover the engine using a thick blanket or fabric to protect it from the weather. Due to the exposed radiator, radiator fluid may spill during the draining procedure. They have a significant possibility of causing substantial damage or even death if they gain access to the engine by any means.

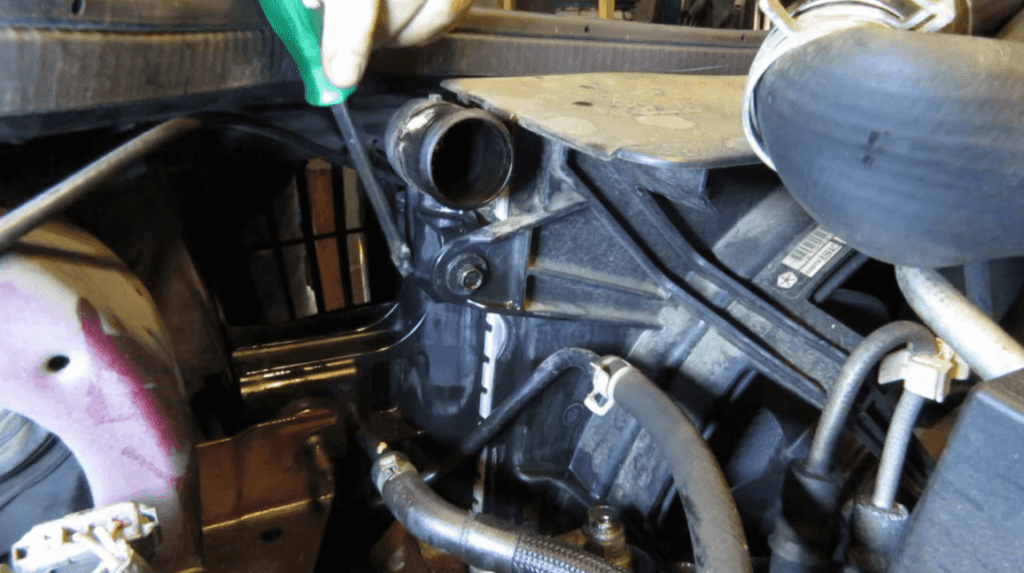

Remove the radiator cap and place a container beneath the radiator plug to allow air to flow throughout the system. Depending on the type, the reservoir plug is often located in one of the four lower borders of the radiator. When the drip stops, remove the lid and allow the liquid to drain thoroughly.

Step 2: Thoroughly clean the place where the leak was located

Before starting the cleaning process, it is essential to determine the source of the leak. Following these guidelines will make it easier to complete your task. As a consequence, you’ll be aware of which places in the house are off-limits for cleaning.

To properly indicate the area, use chalk or a highlighter. Ensure a thorough cleanup of the leaking area. Also, ensure that your radiator is free of all debris and dust.

The use of solvents such as glass cleaner or brake cleaner can facilitate the completion of your task. To absorb as much liquid as possible, squeeze the towel or cloth. Clean it with a wet cloth and brake cleaner or the glass cleaner after it has been used.

Remove any rust or hard particles from the surface of the water with a scraper before cleaning it. Grease and debris can be removed off surfaces with relative ease using a clean towel. Start afresh with a new piece of cloth and repeat the entire process once more.

Add a little water to it, and then use it to clean up any messes from the prior cleaning sessions. Any residues of the solvents used will be eliminated.

Step 3: Thoroughly mix the J-B WELD

The next step is to prepare everything for the J-B Weld. To begin, let’s build the basis for what will come next. J-B Weld is a multi-product firm that manufactures over 50 different items. It is not a matter of selecting the most competent person for the position.

Weld goods are available in two different packing forms. The majority of these items are available in sets of two. To achieve the desired result, you need to combine the elements in these containers.

To the others, only one container is available. With that in your possession, you are prepared to travel anywhere. To achieve the best results, you must mix things up a little.

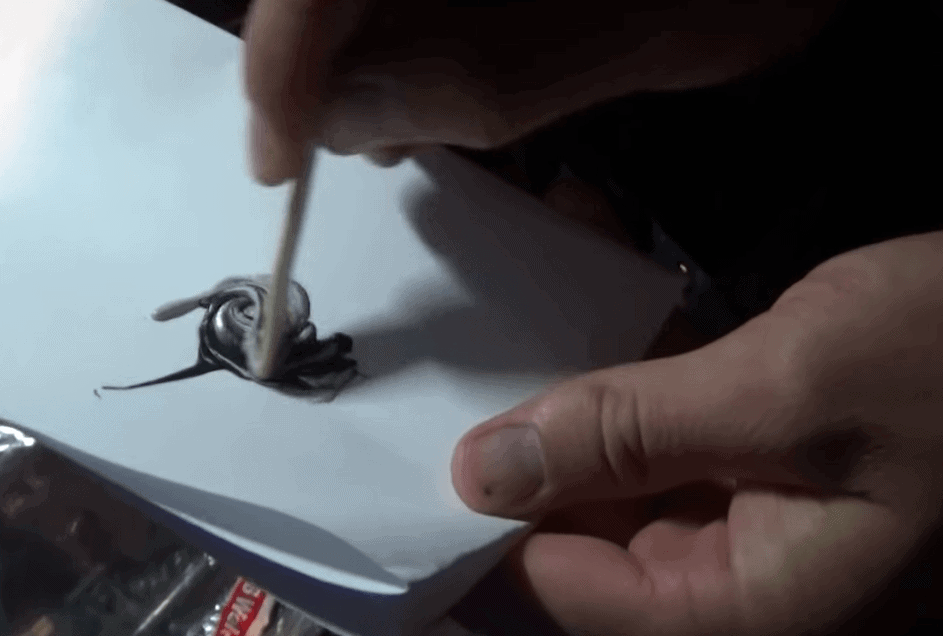

Following that, implement them as quickly as possible. It is recommended to combine and whirl the ingredients using single-use mixing as well as stirring equipment.

Regardless of where the J-B Weld is placed, it will eventually fail due to the mixture drying out and being ineffective. Unavoidably, the plate or whatever else you intend to use will become soiled.

The cardboard packing from J-B Weld may be worth a try. Nonetheless, you run the risk of altering the documentation if you do so.

Utilize a wooden spoon or any other woody objects to combine the contents. However, it would help if you moved quickly, as J-B Weld will soon become well-known.

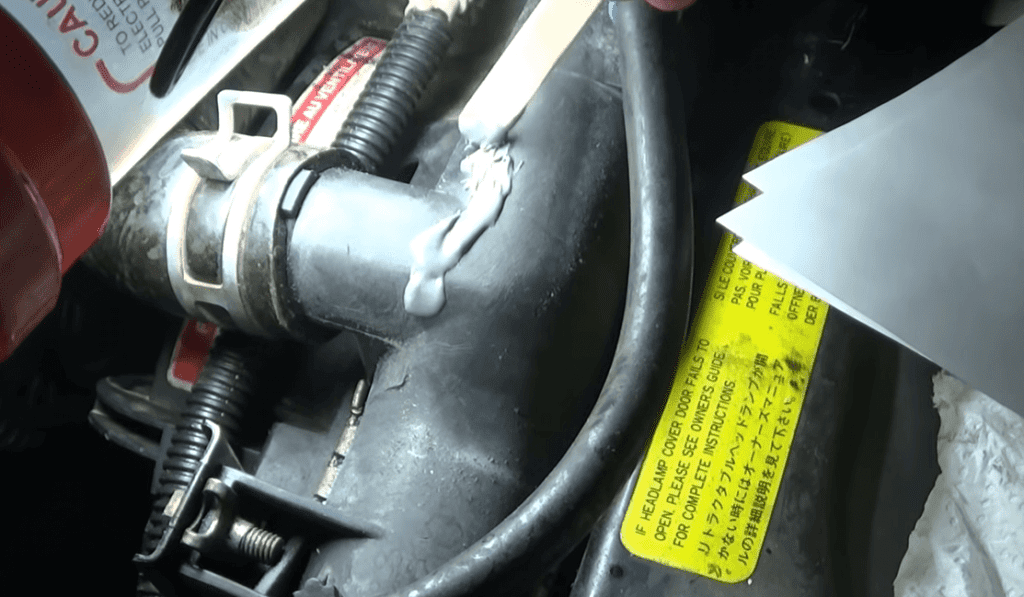

Step 4: Utilizing the wooden tool, apply large amounts of J-B WELD to the entire area where the leak initially appeared

This procedure involves designating the radiator and filling the region with J-B Weld. Utilize a flat object to position the J-B Weld in the desired position. It should be about half the length of the leak to cover the area on all sides completely.

Consider the size of a leak in comparison to a coin. A J-B weld that is one and a half measures smaller will be required for this project. As a result, the hole is covered.

The J-B weld fills the gap due to the forging. Allow 5-6 hours for complete settlement. Additionally, the wound will require an additional 12-15 hours to heal completely.

Step 5: Refill the radiator using clean water

It’s time to refill the radiator after the J-B Weld has completely burned off. Extra caution should be exercised, and waiting until the radiators have been compressed is preferred to the shortest amount of time possible.

Additionally, a heat gun might be a valuable addition. However, one should exercise.

To begin, remove the radiator and the connector that is located beneath it.

Following that, if necessary, the radiator cover can be changed. Antifreeze should then be added to the radiator fluid reservoir. Remove the previous engine cover as the first step.

After that, connect the cells to the car’s battery and switch on the engine. Repeat this process if other leaks are discovered.

You might be interested to read also our another comprehensive article of:

How To Fix Oil Pan Leak With JB Weld

How To Fix A Gas Tank With JB Weld

Frequently asked questions:

- How effective is JB Weld?

Answer: J-B Weld adheres to most surfaces, forming a highly durable and permanent metallic connection that is resistant to high pressure and tremendous heat, making it ideal for vehicle repairs, even those performed inside the engine. J-B Weld can be filed, painted, ground, and drilled just like conventional metal once hardened.

Conclusion

In summary, if there are no leaks after around ten minutes, the task has been completed correctly. Everything is now finished and prepared for your use.

Due to epoxy’s toxicity, I recommend that you use protective gloves when handling the substance. Otherwise, wash your hands well to eliminate any glue that may have been spilled on them. Keep an eye out for any spilled chemicals, such as antifreeze, and clean them thoroughly.

No welding should be required to secure the radiator or radiator brace in place. Hopefully, everything works correctly.

If the radiator is being rebuilt, specific support brackets may need to be unbolted to remove it; however, nothing will need to be welded in this situation. Wherever there is a need, consult a professional.