JB weld is a virtual device many people wish to use to melt metals and join them together. It is the best weld which many people prefer using due to its many benefits such as; it is readily available, and its performance is high when you compare it with other welding machines. It comes with many accessories, including a thread that is essential in its functioning. Despite the thread being practical, it may fail to function as usual at some point.

Yes, a JB weld thread failing to function is a common issue affecting many weld users. For instance, the thread may strip, break, or malfunction, thus leading to the malfunctioning of the whole welding machine. You can fix the issue on your own as it requires some simple steps. But, if you are unfamiliar with how the welding machine functions, it is essential to seek help from a professional. Before beginning the troubleshooting process, ensure you have all the necessary materials.

Fortunately, the article below gives some steps on how to fix a malfunctioning thread with JB welds. Also, it shows some of the reasons why the thread may fail to function, including the FAQs and other information relating to the threads. Please read the article below and have complete knowledge on how to deal with a failing thread with JB weld.

Contents

Steps of fixing threads with JB weld

If your there fail to function, as usual, you can follow the steps below to bring it to correct functioning;

Step 1: collect all essential materials

Before beginning any step, it is essential to have all the necessary materials to help you troubleshoot the thread issue. Some of the required materials include the following;

- A wrench.

- A pin-breaker.

- Cutting tool, especially the cutting oil.

- Thread insert.

- Twist drill.

- Fitting-tool.

Ensure all the measurements and sizes of the tools are correct and match each other. Also, ensure all materials are genuine, and they are functioning as required. In case of any issue, contact the manufacturer to give you more instructions on the materials necessary for solving the problem.

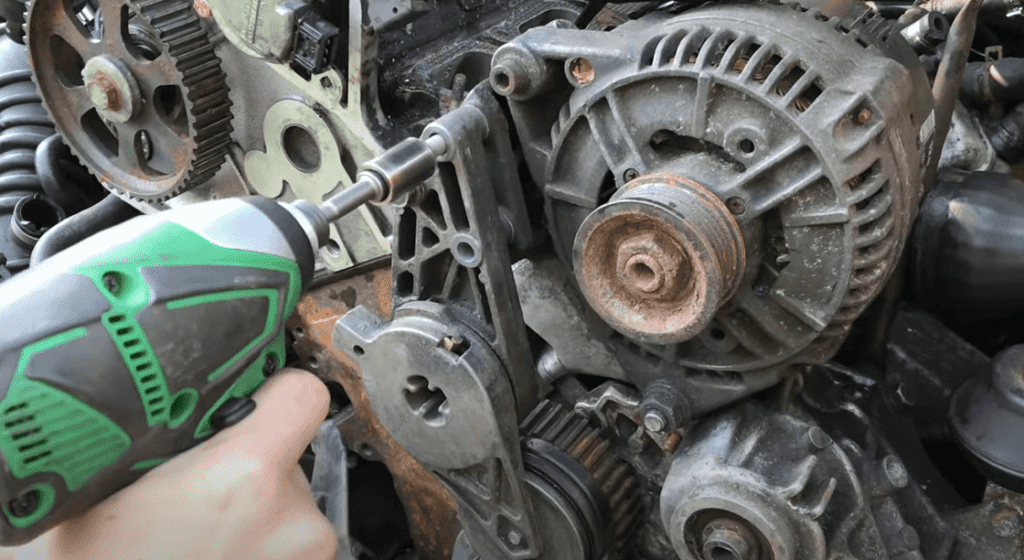

Step 2: Start by drilling the thread

First, find the location of the thread in the JB thread and scrutinize it. Identify any issues relating to it and record them in something like a notebook. Using the drilling machine and twist drill, drill the faulty thread after locating it. While drilling, ensure the size of the thread, twist drilling, and the drilling machine all match.

You may look for some articles recommending the best diameter to drill the thread. Also, check the twist drill the manufacturer recommends. Pay attention when preparing to avoid making the wrong drilling measurements. For example, the best size for JB weld is around 6.8mm Also, remember to review the manufacturer’s instructions in case of any difficulty.

Step 3: Cut the JB weld thread

After successfully making a hole with the recommended diameters, proceed to cut the thread. Now use the single-cut tap machine to complete the processes. First, get your single-cut tap and position it in the tap wrench. Slowly cut the thread using your hands.

You may use the cutting oil as it works more effectively than the hands. Be careful when cutting the thread not to damage other parts near the thread. Also, remember to refer to the JB manufacturer’s booklet on how to handle the threads during the cutting process. Finally, if you are unable to perform the procedure, seek help from an expert.

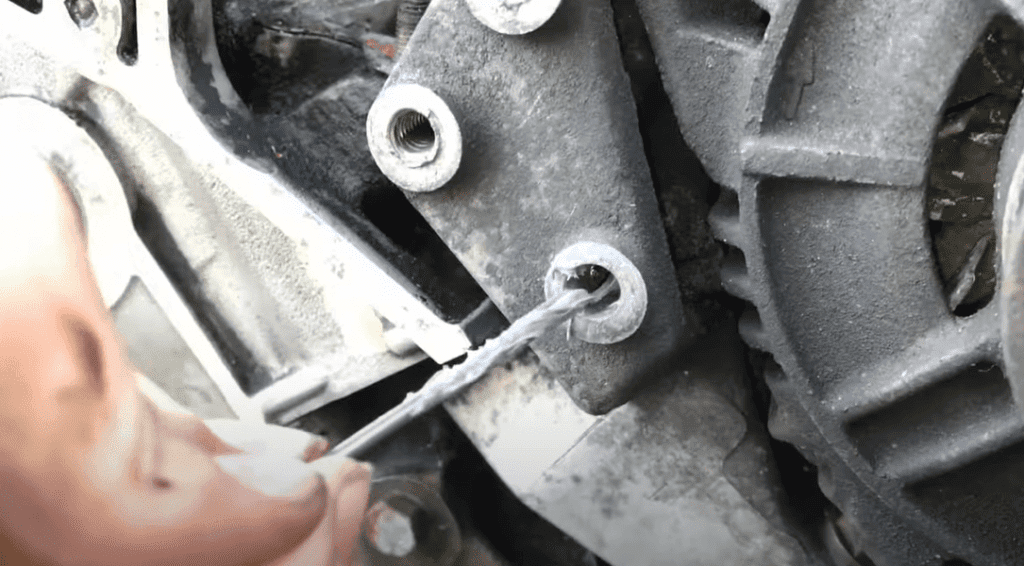

Step 4: thread insertion process

Once you cut the damaged thread in the drill hole, proceed to the thread insertion process. Insert the thread on the appropriate tool carefully. Direct the thread into the hole you have drilled. Ensure you insert it properly and it fits correctly. Check the pin after the insertion process and ensure it is down in the groove meaning, the hook must sit down.

Change the position of the thread by slowly turning it using recommended pressure. Applying too much force may damage the thread and other parts resulting in increased repairing and replacement costs. Ensure you turn the thread correctly since turning in the wrong direction will break the pin.

Step 5: test the thread

After carrying out the process above, try testing the thread to see if it is functioning correctly. If not, try repeating the process above carefully and keenly before seeking help and testing again. If the issue persists, seek help from an expert who will identify the leading cause of the problem and solve it technically.

Step 6: Replace the thread

If the thread is damaged beyond any repair, it is essential to consider replacing it with a new one functioning correctly. Read on the instructions to follow when replacing a thread with JB weld to obtain the best results. Ensure the replacement thread suits your welding and is of high quality to last longer.

Reasons why the thread may fail to function at times

After fixing the thread with JB weld, sometimes it may fail to function due to several reasons, which include the following;

1. Using faulty thread that does not match the welding process.

2. Using the wrong measurements when drilling the hole necessary for inserting the thread. Be careful with the measurements and ensure you use the recommended ones.

3. Twisting the thread in the wrong direction can even break the pins.

4. Not inserting the thread in its correct location.

5. Failure to follow the instructions carefully during the fixation process.

You might be interested to read also our another comprehensive article of:

Fixing Cast Iron With JB Weld- Easy Steps

How To Fix A Gas Tank With JB Weld- Ultimate Guide

Frequently asked questions:

- How can I fix a stripped screw thread that has inserts?

Answer; Follow the steps below;

1. locate the crew and unscrew it

First, you’ll have to unscrew the nut. If you can’t obtain sufficient hold to extract the nut because the bore is entirely worn, you’ll have to make a drill in the middle of the screw and have a nut extractor on ready.

2. Wash the rest of the threads

After you extract the screw, wipe the other threads with a clean cloth, pressurized air, and lubricating oil. If you have a Shop-Vac, it will come in handy throughout this operation.

3. Select the appropriate drill size

Inspect the drill diameter indicated on your coil-type threaded insertion box to ensure that you can bore the unique tool to that diameter. A drilling stopper will assist you in keeping the hollow cavity when cutting. Seal the tap with cutting oil and back that up now and then to clear out any inlays that may become disturbed if this isn’t done.

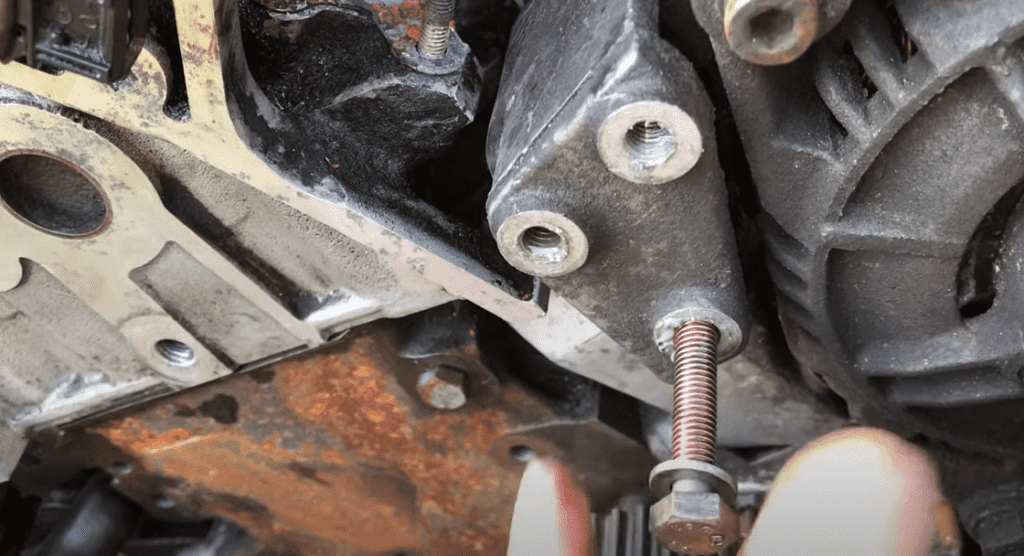

4. Onto to the Install Tools, Input

After that, push the thread insertion ultimately into the installation tool. If the thread insertion is put correctly, a button on the bottom must be firm.

5. Put the Bolt in the thread

The thread insertion must be treated with lace solution at this phase so that you can screw it into the new threads. Ensure that the thread insertion is completely level with the substrate at this stage. Needle nose pliers will come in handy for removing the heating coils connector.

Conclusion

The process of fixing the thread with JB weld is simple and has straightforward steps. The information above provides the information you may wish to know if you want to improve your thread using the JB weld. Follow the steps above carefully if you’re going to obtain some of the best results.

While fixing the thread with JB weld, take precautions to keep both the thread and the welding machine last longer. First, check the type of thread you are using if it suits the welding process. Also, service the device more often to keep it in good shape to last longer. Finally, it is always important to review the manufacturer’s instructions for more information.