Well yes, Contrary to most of the popular beliefs, wire feed motors for MIG welders, not working is a commonly occurring problem with almost all models. However, miller MIG welder wires feed issues will often have a domino effect.

Moreover, this implies that a simple problem may trigger other additional problems. For instance, overhead costs may be due to late delivery or unnecessary downtime.

In this article, we will take you through a step to step procedure on the possible causes and ways to fix the problem. Most importantly, you need adequate time to check out why and where the welder has feed problems.

Besides, you can also learn from the FAQ session we have prepared at the end of the article. So you don’t want to miss it. So let’s jump in and get some work done.

Contents

Tools You Need To Fix This Problem

Here are some of the things you may need before you start to check the possible causes and how to fix the wire feed motor of the MIG welder, which has stopped working.

1. Welding framing jig

2. Speed square

3. Sheet metal gauge

4. Metal file

6. Metal brush

7. MIG pliers

8. Soapstone

9. Angle girder

10. C-clamps

11. Chipping hammer

Below is a guide which will be of help to figure out probably the possible reasons, which are responsible for your wire feed motor on your MIG welder not working. Besides, for starters probably, there could be a few places to check for tear and wear, and also maintenance.

MIG Welder Wire Feed Motor Not Working: ways to fix

1. Wire quality

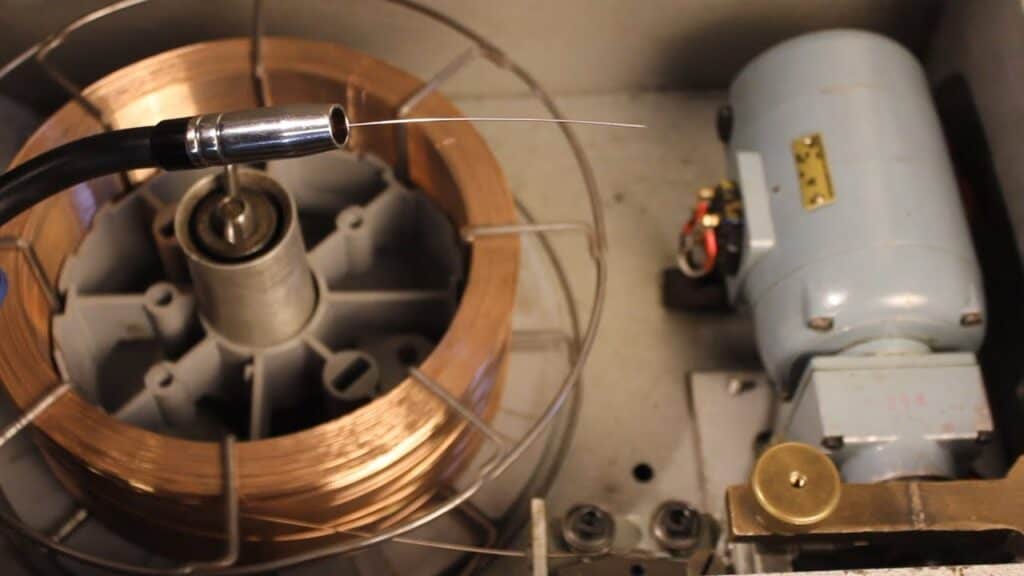

Does the quality of your wire matter when it comes to the issues of MIG welders? Some people may tend to overlook the fact that wire quality affects your wire feed motor and make it not work efficiently. Indeed, many MIG welder wire feed issues often arise at this point.

Factors like moisture accumulation, probably due to lack of maintenance or long duration of inactivity, can make weathering and cause rust, which at last will clog your system. If you identify rusting as the problem causing, try to unspool your wire feed till you get a clean segment of wire and use it.

When you maintain your wire feed motor, it will go a long way to determine the worthiness of your machine. One of the basic tips to maintain is dabbing your feed wire with a blanket or garbage bag after removing it out of your motor.

2. Tension in your spool and drive roller

Some of the MIG welder wire feed issues come at the point of the spool and drive rolls. When the tension is too much on your wire spool, it will automatically cause a short tear and wear; however on the other side of the tension is very little in your spool, you will encounter a bird’s nest mess for you to deal with.

Having this in your mind, it is of importance to have a good level of hub tension that can allow the wire spool to turn comfortably. Moreover, if the drive rolls are working under lots of pressure, your wire may be permanently damaged by reneging and affect the wire feed motor.

A wire which is deformed will be counterproductive on your contact tip; this may lead to reduced overall capacity. Since we don’t have an exact measurement unit to define the level of tension that is adequate for wire spools, a few tips can be used to have an optimal level.

Firstly try to lose your drive rolls, then adjust their alignment so that they can align against the gun’s inlet well. After that, increase tension while feeding the wire on another holder, for instance a wooden block. Just continue increasing tension till your reach half turns away just from wire slipping off your holder.

You also check if there are any potential signs that can indicate wear and tear of your wire may be experienced over some time. However, if there is a need for you to tighten the wire more than normal, check if the feed meets the necessary settings and parameters.

In case you check out and find out that the MIG welder wire feed motor is still not working, perhaps the drive rolls require to be changed out. It is important to ensure that inlet guides that lead to the gun have matched the size of wire you are using. It should be done without any grooves and the correct size to reduce your wire feed motor issues.

3. Gun liner maintenance

The only way to avoid MIG welder wire feed issues is to ensure that the gun liner is squeaky clean. Again it must have an adequate matching size of the wire you are using.

If your wire spool may be over-tensioned, then wear and will occur by losing flakes, which will accumulate over time just within your gun liner. Sometimes users tend to lubricate wire which is fed into the gun liner by pretense.

The issue is that it can lead the wire to damp for a long period, which leads to rust accumulating; hence it can make wear and tear faster. Here are some of the things which you can be done:

Firstly, you can use compressed air, which is low pressure to blow the gun liner to remove any particle accumulated clogs that can open up easily. Secondly, gun liners are not expensive, and they need to be replaced regularly to avoid unnecessary MIG welder feed issues.

4. Contact tip maintenance

One of the essential features of your MIG welder is contact tips. They are in direct contact with your welding puddle; hence they can be distorted over a certain period.

Moreover, your welding spatter can also cause wear and tear and also clogging. Some of the things you can do to solve the problem are: firstly, ensure that the wire aligns well against the contact tip ID. The size can sometimes be distorted because of the tip’s direct contact with your welding puddle.

Secondly, check if the tip has any grooves. This is because of excessive tension. Finally, replace the contact tip regularly to increase the overall quality and machine’s longevity.

You might be interested to read our another article of: Gauge Wire For 220v Welder

MIG Welder Wire Feed Motor, Not Working-FAQs:

- Question: Why does my MIG welder stop feeding wire?

Answer: if the trigger switch is damaged, or even when control leads in the gun cable are deformed. In case you find that is the issue, you need to replace it. If your drive rolls are moving, but the wire is not feeding, the problem is caused by low drive roll pressure.

- Question: How do you fix a bad MIG Welder wire feed motor?

Answer: There is no easy way to fix it. Rather you can grind the whole sucker off and start afresh.

- Question: How do you unclog a MIG welder wire feed motor?

Answer: You can knock it off or use your pliers.

Conclusion

There are many reasons why the MIG welders wire feed motor has stopped working. However, the points of inspection and maintenance always provide you with a starting point.

However, if you find that after checking through the above possible causes and how to fix them, the wire feed issue is not solved, then it is high time to contact the manufacturer or a professional to help you.