J-B Weld should not be used on exhaust manifolds or catalytic converters because of the high temperatures that can be reached in exhaust systems. When the continuous heat is more minor than 450 °F, our High Heat epoxy glue stick is recommended, but only in the most extreme cases.

In the case of an exhaust or muffler leak, JB Weld is an excellent choice. An exhaust leak can be repaired using epoxy and a little fabric. Leaky exhausts/mufflers can be fixed with JB Weld epoxy, or if the hole is tiny enough, you can use JB Weld to close it up entirely.

The following article will offer you the best way to proceed if you have an exhaust leak and need to repair it using a J-B weld. The following post also includes answers to other commonly asked questions, which is an excellent addition. To effectively repair your radiator, you must pay close attention to the directions in this article and adhere to them strictly.

Contents

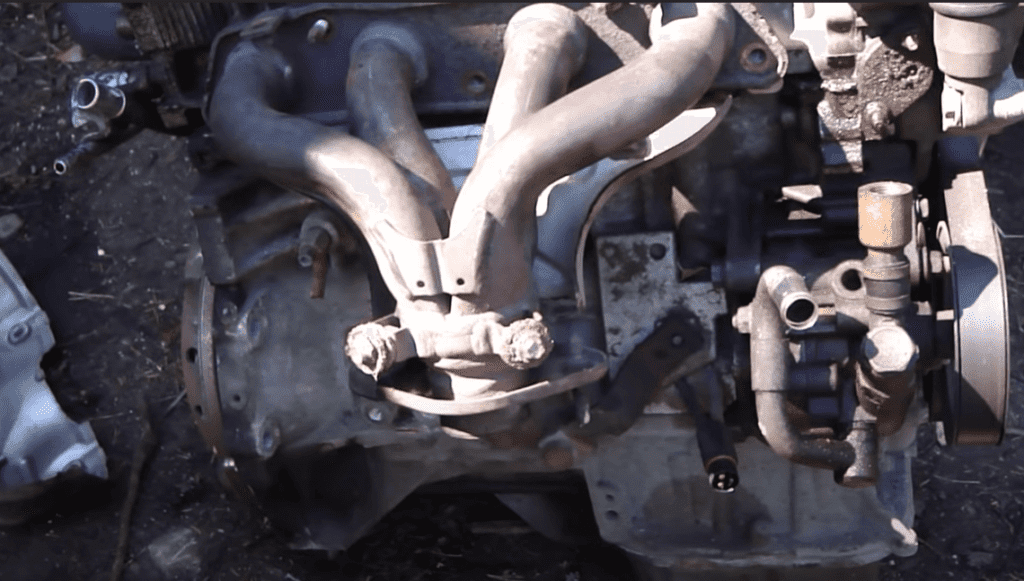

Fixing A Leaking Exhaust Manifold

i. Gaskets and seals that are damaged should be replaced. To remove the manifold, you’ll need a socket wrench and a toolset.

ii. Examine the flange in which the exhaust manifold attaches to the engine. Unless there was a gasket present when the manifolds were removed, this is quite normal.

iii. Disassemble and repair broken manifolds if possible, or substitute them with a newer version.

- A dark grey hue is achieved in 4-6 hours at room temperature using J-B Weld adhesive. In 15-24 hours, a complete recovery is achieved. This product has a tensile of 3960 PSI that cures to a firm bond in one to two hours after being applied. When properly fixed, it has the ability to endure temperatures of up to 550oF.

- Since most repair businesses do not have the necessary equipment, JB Weld Extreme Heat has become a popular solution for high heat restorations. For example, Extreme Heat is an air-curing epoxy solution that can resist temperatures of up to 2,400F for an extended period, unlike normal JB Weld epoxy.

Finding a Leak in an Exhaust Manifold

- Step 1

To properly repair an exhaust system, it is necessary first to determine where the problem originated. Because the exhaust system heats up so much, it may be difficult to notice an exhaust leak and determine the source of the malfunction. It’s best not to touch anything close to the exhaust system if you’ve been driving about in the car in the last several hours because it could burn your hands. Wait till it gets to room temperature.

- Step 2

Begin by performing a visual assessment. The exhaust manifold can be found by opening the hood and looking under it. It is the location where the combustion products from the vehicle’s engine will be released into the atmosphere. It will very definitely be eroded and will be made up of several tubes or one single large tube. Due to the possibility of a heat shield concealing them, proceed with caution.

- Step 3

Follow the pipe back underneath the automobile to the back of the vehicle. Make a visual inspection of the pipe for cracks or locations where it has cracked or separated. As you make your way back, take a close look at each of the emission ports. The presence of one or more catalyst converters, repeaters, or even mufflers may be apparent.

- Step 4

To create this, large metal cylinders or boxes must be joined together along with the exhaust piping. Cracks, fractures, and folds should be checked on each of them. Other defects in the exhaust pipe may appear the same as the signs of a leaking exhaust pipe in some cases. As a result, it is vital to ensure that the leak is coming from the manifold before proceeding with any additional repairs.

#Unusual sounds

You can also conduct a proper inspection to determine whether an exhaust manifold leak exists. An exhaust system gasket leak is usually detected when you turn the ignition key and notice an increasingly louder sound originating from the engine’s vicinity when the engine is being started.

Remember that a gasket is situated between the exhaust system pipe and the engine for your convenience. The gasket, such as the pipe, is subjected to constant heating and cooling. Inspecting the gasket to determine if it has a flaw is necessary if no fracture or leak is coming from the pipe.

When you press your foot down on the gas pedal, pay attention to see if you can hear anything unusual. If you detect noises like air leaking out or a faint whistling, you may have an issue with your air conditioner.

Most drivers have difficulty distinguishing between various engine sounds, exhaust noises, and even a vacuum line leakage in their vehicles. Concentrate on the precise time at which the noises occur. If you can spot the problem before sending your car to the mechanic, self-diagnosis can save you a lot of time and frustration.

How An Exhaust Manifold Works

The exhaust manifold is the first component you’ll notice when it comes to your car’s exhaust system. In this case, it is connected to the automobile engine and collects pollutants from the vehicle.

Air and fuel mixtures from the car’s engine’s multiple cylinders are contained in the exhaust manifold. Each cylinder’s fuel and air mixture is collected by the intake manifold, regardless of how many cylinders there are.

Because of its extraordinarily high temperature, the exhaust manifold not only collects all of the engine gases that have been used, but it also consumes totally any squandered or incompletely burned gases. The exhaust system’s initial oxygen sensor is also located in the manifold, and it is responsible for monitoring the amount of oxygen flowing through the exhaust system.

The oxygen sensor analyses the oxygen level in the atmosphere. It communicates with the fuel injection system, determining whether to increase or decrease the amount of oxygen in the atmosphere and the gasoline mixture used to provide the engine with electricity. The usage of exhaust headers rather than standard exhaust manifolds is becoming more common in automobiles.

The situation is particularly dire with high-performance cars when increasing horsepower takes priority above achieving maximum performance. Because headers are designed to have reduced fuel flow limits, they can remove exhaust from the system rapidly and efficiently. However, depending on how they are designed, they may impact power at lower speeds and higher engine speeds.

You might be interested to read also our other comprehensive article of

How To Fix Leaks In Copper Pipes

Frequently Asked Questions:

Is it possible to repair a JB weld with Extreme Heat?

Answer: If the two pieces cannot be repaired with JB Weld Extreme Heat, they must be replaced. One of the exhaust manifold nuts snapped off on this cylinder head. Extreme Heat cannot fix this. This calls for JB Weld Original.

Conclusion

To conclude, while replacing an exhaust system with a header is conceivable, it is uncommon for the inverse to be true without causing significant performance degradation. According to technical terms, the exhaust manifold functions as a funnel, gathering all of the pollutants generated by the engine. After the contaminants have been entirely burnt in one spot, the contaminants are released into the rest of the exhaust pipe through the manifold.

Occasionally, if the pipes get broken or rusted, they might generate an exhaust leak, resulting in the vehicle experiencing performance concerns. Because of the loss of backpressure caused by an exhaust leak caused by a damaged pipe, a vehicle’s power, acceleration, and efficiency can all suffer due to the problem. Once you follow the given guidelines and still do not fix them appropriately, seek professional help.