Although JB Weld is not recommended by most plumbers, still you can use it to put a stop on a leaky copper pipe. However, this substance is not good at working on plastic surfaces; it can do wonders on your copper pipes.

I know you are now wondering how to go about this action; don’t worry because the knowledge is here. We promise to take you through the entire process and at the end; the leaky copper pipe will be the thing of the past. Our research should help you fix copper pipe leaks with JB Weld.

In our article, you will know how to JB weld leaky copper leak. The approach is famous for creating rigid bonds on dry surfaces, blocking tiny leaks in your copper pipe. From the same article you will understand how long to leave the treated area for hardening.

Contents

Tools required

Consider having the following tools or items whenever you want to JB weld a leaky copper pipe. They include:

- SharkBite Couplings

- Duct tape

- Tubing cutter

- Propane torch

- A utility knife

- Dry cloth

JB weld to fix copper pipe leak (guide)

Below are reliable steps to direct you throughout the entire process;

Step 1: Locating the leakage

Maybe you should wear gloves; it’s highly recommendable. Sometimes spotting water leaks is simple, but can be different with hidden copper pipes. For example pipes in the ceiling can be challenging as you can only see water marks. But with naked pipes, it’s straightforward to locate the leakage.

Step 2: Draining the water lines

After identifying the suspected area, the next action will be to stop water from running in the pipe. Doing so is necessary so as to empty the pipe entirely.

If it’s in your bathroom, you should open 2 faucets linked to the water line. The first faucet should be located below the leakage to let in enough air in the pipe to encourage complete drainage. Alternatively, you can drain water from the pipe via the laundry tub.

Step 3: Wiping the leak

Now with the help of your dry piece of cloth, wipe down the place and observe if water starts beading up. In case the water stops, don’t rush to repair the pipe; it’s too early. You should therefore allow the wiped place to completely dry; give it something like two hours.

You need to understand that JB weld will establish a weak bond in a watery surface. It will not resist pressure for the leakage.

Step 4: Heating the area surrounding the leak

I remember telling you that you should have a propane torch; it’s highly recommended. If you are good at waiting; you don’t require this item. However, to fasten the drying process, a propane torch remains essential. This torch will help to convert the water into steam that will eventually evaporate via one of the faucets.

Now, it’s advisable to wait for the dried pipe to cool down, not to end up with burns. Hold your horses for something like 20 minutes before starting working on the leaky copper pipe. If everything is cool, move to step 5.

Step 5: Preparing the putty, ready for the task

Under this step, you are required to take a reasonable putty amount from the stick. If you are keen, the substance features two varying colors. Therefore, you should knead it thoroughly with a stir stick or your fingers.

The mission here is to ensure the putty attains a uniform color before thinking of initiating another action.

Step 6: Applying the putty

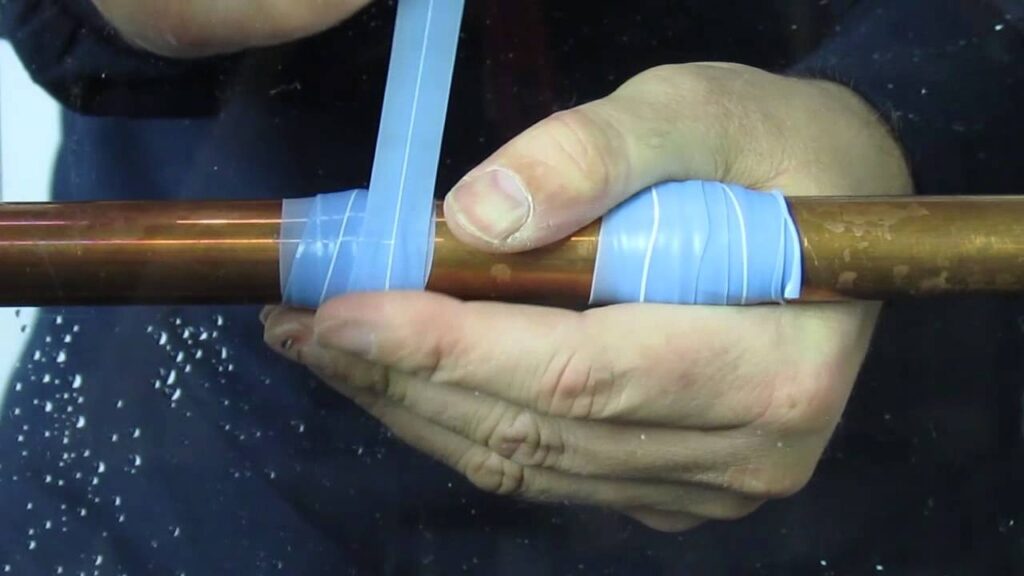

After confirming that the putty has attained uniform color, start wrapping it around the pipe. During the application, you should also try to squeeze the substance into the leak to cover the hole. Besides, you should press its edges to secure them on the pipe.

Remember, the action should not be only to seal the hole since the pressure of the water will blow the substance from the pipe. Do it with great care and don’t regret the action. Once you are comfortable with putty application, move to the next step.

Step 7: Use duct tape to protect the putty

Covering the putty is highly recommendable as it helps in reinforcing it. It’s therefore better than relying only on a mere patch. On the putty container, look for the specified time you should give the substance to fully get cured.

Approximately, an hour or two hours can still do, but you can even extend for remarkable results. You should therefore not rush using the water line; hold on.

Step 8: Testing the artwork

If things have been running well, it’s now time to award yourself some marks for the work done. Start by closing the faucets before diverting water back into the line. Pay close attention to the repair and if it continues to leak, chip or scrap off the putty. Repeat the procedure with fresh putty on the leak.

But, if you see nothing like water droplets, give yourself a pat on the back because your efforts yielded something.

You might be interested to read also our another comprehensive article of:

How To Fix Oil Pan Leak With JB Weld

How To Fix Exhaust Leak With J-B Weld

FAQs:

- Can JB welding stop leakages?

Of course yes, this approach tends to seal or plug patch holes and leaks and cracks. The substance is therefore ideal for plumbing, fuel tanks, shower and tubs, spa and pool, water tanks and boats. JB weld is great since you can tap, file, drill, paint, and sand. Remember, setup can occur even below the water.

- Is it advisable to patch a leaky copper pipe?

In situations where a copper water pipe leaks after corroding, or bursts as a result of freezing, work on it immediately. Sometimes the pipe must be replaced in case the leak is worse. Alternatively, you can cut a small piece of pipe and solder it on the typical pipe with the help of pipe coupling. On top of the patched area, you can cover it with duct tape and smile.

- Is there anything you can use on copper pipe instead of JB weld?

Yes, there is an alternative product on the market known as Harvey Epoxy Putty. This substance works similarly to JB weld; that is to stop leaks in cracked surfaces. However, you will get better results on dry surfaces; it completely blocks small leaks in either galvanized steel or copper pipes.

- Can I use Gorilla Glue to stop a water leak?

You can use Gorilla Glue Waterproof Patch and Seal Tape to fix a leak gutter within the shortest time possible. This implies that you don’t have to worry about using it if you fail to get JB weld. Just buy Gorilla Glue Waterproof Patch & Seal Tape to instantly stop water, air, or moisture from the pipe.

Final words

Any DIYer would never neglect such important information. Since we care much about you, we thought it was noble to research on your behalf.

The report has provided enough information so that you can JB weld your leaky copper pipe. Therefore before seeking the help of an expert, you should consider subscribing to our information.

The steps are simple and also involve simple tools and materials. Don’t worry about the knowledge; go through our article.